Refined Chinese Green Tea is a granular green tea with good solubility.

Teabag and flower tea processed from Refined Green Tea are highly favored by consumers.

In the early 1970s, China successfully produced Refined Green Tea, which was mainly used as a raw material for scented tea. Flower tea infused with broken green tea has a stronger aroma absorption than bar roasted green tea, and can save about 20% in flower amount. Bagged tea processed with green broken tea has the advantages of excellent quality, good solubility, and low price, and is highly welcomed by consumers. Vigorously developing the production of Refined Green Tea is of great significance for expanding the variety of tea sold abroad in China, enhancing the competitiveness of tea in the international market, and alleviating the serious problem of unsold low-grade tea in domestic sales.

Refined Green Tea is mostly made from mid to low grade fresh leaves, and the harvesting of fresh leaves can be mechanized. Mechanical tea picking can improve labor efficiency and reduce costs. Research has shown that mechanical tea picking can increase labor efficiency by 18-20 times compared to manual tea picking, reduce tea picking costs by more than 70% per kilogram, and ensure good tea picking quality. Processing green broken tea with medium to low-grade fresh leaf raw materials can increase economic benefits by 15% to 20% compared to processing other bulk green or black teas. If the ratio of summer and autumn tea is properly configured, it can also enhance the flavor concentration of green broken tea. Green broken tea is generally divided into three types and four colors: granular tea, final tea, and sliced tea. 1. No.2 tea is a granular tea, which is the main color of green broken tea. The extraction rate required for screening should be above 74%. No.3 tea is the final tea, and No.4 tea is the sliced tea. The quality characteristics of green broken tea: the granular tea is compact and granular, the sliced tea is wrinkled, and the final tea is sand like; The color is green and moist, with a strong and refreshing taste. The soup color is bright yellow green, and the leaf base is yellow green.

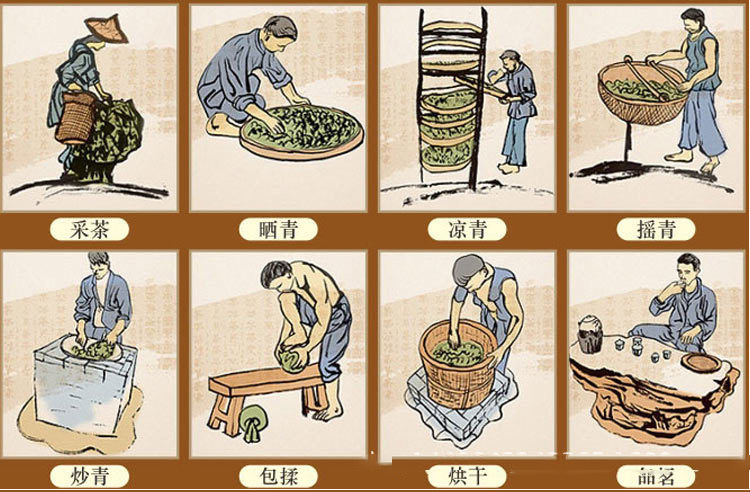

The processing of green broken tea includes processes such as withering, kneading, and drying.

Extermination

The technology of killing green tea with broken leaves is the same as that of frying green tea, that is, high temperature killing, first high and then low; Combining throwing and blocking, throwing more and less; Young leaves kill old ones, old leaves kill young ones. The degree of withering is slightly heavier than that of general roasted green tea, with a moisture content of about 58%. If the water content of the killing green leaves exceeds 60%, there will be more 8-hole face tea, with loose particles, more sheet-like tea, and the tea juice will be lost during kneading and cutting, which will affect the flavor concentration and bring certain difficulties to the block separation and screening; The moisture content of the green tea leaves is below 51%. Although the particles are compact, the amount of tea leaves increases.

The quality of using a drum type killing machine to kill green tea is better than that of a pot type killing machine, and the labor intensity is low, which meets the quality requirements of green broken tea and the mechanized operation of tea making.

Rubbing and cutting

In order to make the taste of Refined Chinese Green Tea strong and refreshing, it is required to destroy the leaf cells as much as possible during the kneading and cutting process, so that the tea juice can be quickly extracted during brewing. Therefore, the 709 and 705 rotary kneading and cutting machines are generally used for the kneading and cutting of green broken tea, with the former used for initial cutting and the latter for re cutting. Due to the high squeezing pressure of the knife, the kneading blades pass through the machine for 20-24 seconds, and the output blade temperature is about 10 ℃ higher than room temperature. It should be matched with the block breaking screening machine to form a kneading and cutting assembly line. After kneading and cutting, the sifted face tea (4-hole face tea) through the block breaking screening machine generally accounts for about 40% of the total amount each time. These sieved tea leaves mixed with the initial kneaded leaves are beneficial for a fine and tight appearance, with fewer head teas, and can be continuously processed. The tender raw material leaves about 450kg per hour. Generally, an increase in leaf amount leads to a decrease in granular tea and an increase in sliced tea.

Desiccation

Refined Green Tea has a small body and fast biochemical changes. When kneading and cutting leaves, they should be baked in a timely manner. When drying, adopt the method of high temperature, short time, and thin spreading. Generally, the drying process is divided into two stages. The first stage is at a temperature of 100-110 ℃, the second stage is at a temperature of 50-85 ℃, and the middle stage is spread and air dried once. The spreading and drying process must be short and thin to achieve the goal of evenly drying. It is advisable to control the moisture content of dry tea at 3% to 5%.